Lets grow together

Get our customized printing services for your clothing brand

Printing plays a prominent role in how a garment looks and feels. It’s horrible to neglect the importance of printing methods while choosing clothing manufacturer for your brand. Interestingly, brands pay closer attention to printing methods because of increasing marketing competition due to the awareness in people. Therefore, every brand has to provide the best to become the top brand in people’s minds.

The process of printing your design into fabric is critical because your product is wasted if there’s a mistake. Due to the advancement in technology, there are several screen printing methods. At Baagh Enterprises, we offer a wide range of printing methods so that you can choose the desired method.

What we offer

printing Types for Clothing

Choosing a right printing method is important. At Baagh Enterprises, we guide clothing brands about which method thye have to choose with respect to fabric selection. So, you don’t have to worry about this selection. We have wide range of printing options depending on fabric types and brand choice.

Water Based / Screen Printing

In water-based screen printing (commonly known as screen printing), water-based ink formulations consist of pigments or dye-suspended rather than solvent-based chemicals. The ink is applied at the top of the screen, and a squeegee is used to press the ink through the open areas of the stencil onto the substrate. The printed garment is then dried using heat to set the ink and ensure longevity and durability. It’s best to use on such garments of a clothing line that requires a soft-hand feel, breathable finish, and suits best on light-color fabrics because of the transparency of the ink. It has some great features for our environment, i.e., the inks contain less volatile organic compounds (VOCs), and no harsh chemicals are used for the cleanup. And that’s how it stands out from other printing methods.

Silk Printing

Silk printing, also known as serigraphy, is a super-versatile method used for various surfaces, including textiles, paper, plastics, metal, etc. The silk printing process starts with creating a stencil of the design on a mesh screen made of silk, polyester, or nylon; then, the stencil areas are blocked out to prevent ink from passing through them, leaving the design open and exposed on the screen. The ink is applied & pressed through a squeegee on the surface. It’s commonly used for T-shirts, hoodies, tote bags, and other apparel items and is best for medium to large print runs because of its high quality and consistent results.

Discharge Printing

Our washing process ensures that your brand’s garments achieve the perfect look and feel from you, a vintage-inspired fade or a soft and luxurious finish; we’re here to help you with our expert team without settling for the ordinary.

Glow-In-The-Dark Screen Printing

It’s a unique printing method possible because of the technology resources. The dark printing method allows the design to be bright and emit light in the dark after exposure to light sources. It feels artistic, and we love to pull off our client’s requirements while giving input on our creativity. The application of the ink of fabrics is very similar to other printing methods; however, the ink used to produce the glow-in-the-dark effect is special. It contains phosphorescent pigments that absorb and store light energy when exposed to light sources such as sunlight or artificial light. When the light gets removed and it’s dark everywhere, it uses the stored energy and gradually releases it in the visible form, creating a glow-in-the-dark effect. You can choose this if you’re working on novelty items.

Foil Printing

You may have heard this one called foil stamping or blocking. When you apply a metallic or colored foil to a surface, aka fabric, using heat and pressure, that’s what foil printing is all about. It’s normally used for high-end packaging such as boxes, bags, and labels to add a touch of luxury. You can also use it for weddings, greeting cards, or stationary items. Moreover, some brands use it to add metallic-designed T-shirts, hoodies, bags, etc, to their clothing line. It reflects a shiny finish when the process is completed, often used to differentiate the brand.

Flock Printing

Flocking is done after applying a layer of fibers called flocks on the surface to create a velvet-like texture. After completing the traditional screen printing method by applying the ink and drying it out, there’s an extra step: applying the electrostatically charged flock fibers to the adhesive-coated areas, which causes them to adhere to the surface and create a raised and velvet-like texture. After that, the extra flock is removed, and the ink is dried to complete the flock printing process. As a result, visual interest is attained due to the soft textured finish of flock printing. This printing method offers a tactile effect, which is its USP.

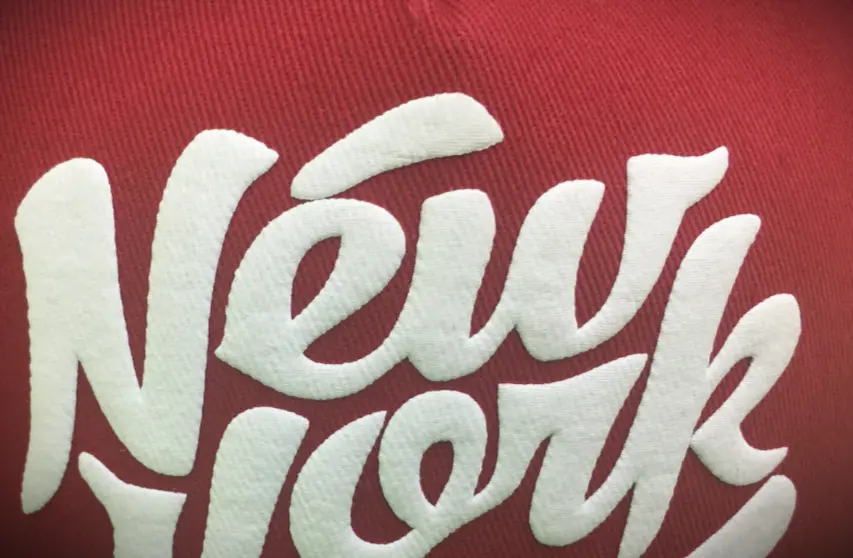

Puff Printing

Whether you’re looking for a printing method for creating promotional products, branded items, T-shirts, sweatshirts, jerseys, or logo printing and lettering with dimensional effect, you can choose puff printing without hesitation. It begins by creating a screen-printing design on the substrate using traditional methods. After the design is printed and dried, puff ink is screen-printed on top of the design in the desired areas. Then, it’s exposed to heat to get a puff print as a result. It’s a unique printing method to achieve a visually appealing effect as a clothing brand.

3D Screen Printing

Traditionally, screen printing is all about printing the design onto the fabric with ink, but 3D printing has a significant change. This interesting process starts after the digital version of the desired result is designed in computer-aid design – CAD software. The 3D printer builds the object layer by layer from the bottom up after the digital mode is sliced into horizontal layers. To create a 3D dimensional product, every layer fuses with the previous one. It’s commonly used in prototyping. It has several advantages over other printing methods, such as rapid prototyping, design freedom, cost-effectiveness, reduced water, etc.

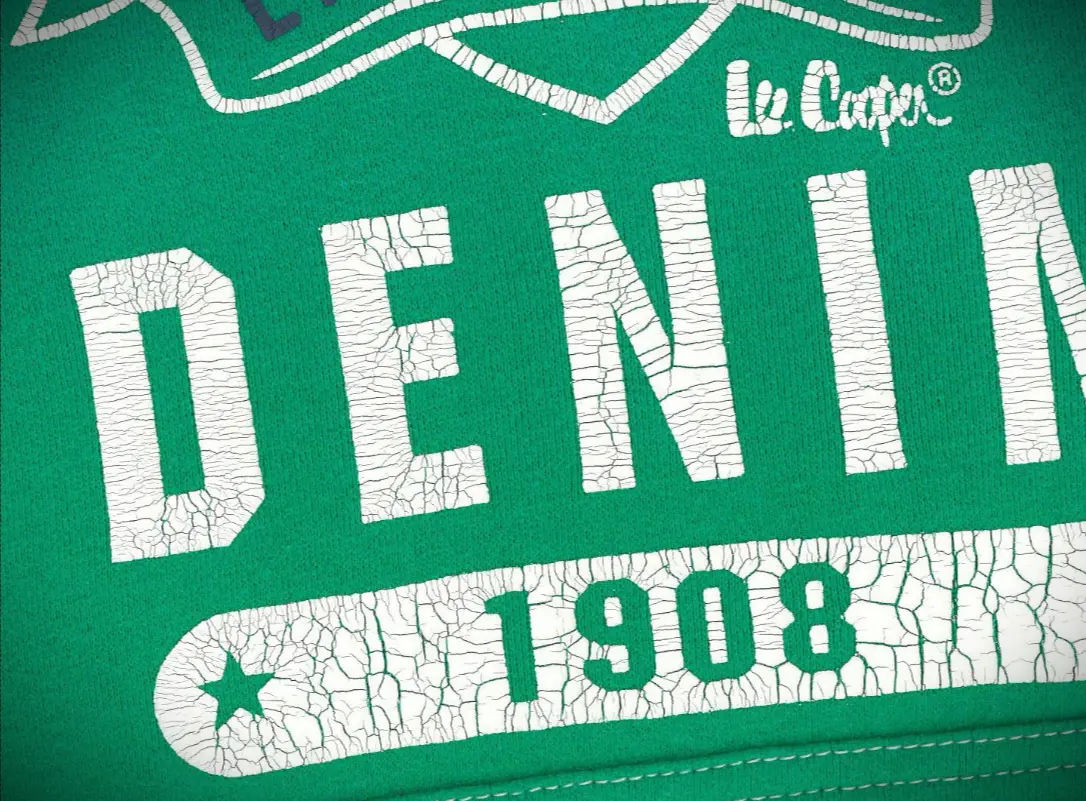

Crack Printing

Crack printing is used to create a distressed and aged look & feel on printed designs, with the help of special crackle ink formulations that split apart when dried, which gives us the desired result, i.e., revealing the lower layer of the garment. It can be applied on T-shirts, hoodies, and sweatshirts but is mostly used and popular for artistic purposes, i.e., art posters, decorative items, etc. And because of its different visual effects, it attracts more eyeballs toward the garment. While it’s famous for its artistic ability, it is also durable and long-lasting, making it a BIG YES for those who want artistic printing.

Dye Sublimation Printing

Dye sublimation is another simple yet effective printing process that produces high-quality prints on textiles and other items. The method is used for casual apparel items, i.e., T-shirts, jerseys, leggings, and sportswear; however, it’s more popular for soft signage, banners, flags, trade shows, promotional products, keychains, mugs, phone cases, or even home & bedding accessories, i.e., curtains, blankets, cushions, etc. The result of the dye sublimation process is vibrant, wash-resistant, durable, and long-lasting prints that make it appealing to people.

Digital-DTG Printing

Digital printing or direct-to-garment (DTG) is a modernized printing method. The designs are printed directly onto the textiles using specialized inkjet printers after the design is prepared on graphic design software or scanned from a physical image. It works best on multi-colored garments because the computer makes it technically impossible to make a mistake in printing the exact design you finalized; contrarily, there are still chances of errors in other printing methods. Because humans make mistakes, it typically has a quick turnaround, reduced waste, cost-effectiveness, and versatility. Digital printing is a green printing method that automatically supports eco-friendly printing activities.

Sticker Heat Transfer Printing

The designs are transferred onto the various surfaces using heat and pressure in sticker heat printing, aka heat transfer vinyl (HTV) printing. Then, the designs from the vinyl sheets are cut and applied to the desired surface using a heat press. This method is used to decorate common apparel items such as T-shirts, hoodies, hats, and jackets. You can create customized designs and give them to us, and we’ll print those on your garments production.